China’s power cuts are not groundless

1 With the price of coal soaring, China’s coal-fired power generation has long been overwhelmed

The main power generation is thermal power and hydropower, accounting for 90% of the total power generation, of which thermal power accounts for 72% , hydropower accounts for 18% , the remaining 10% is nuclear power 4% , wind power 4.5% , solar energy 1.5% , geothermal power, tidal power, bio-electricity can be ignored.Thermal power generation is mainly dependent on coal, coal prices

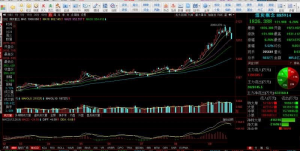

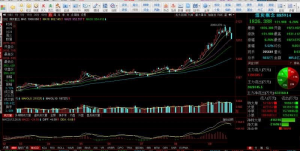

Since march, coal stocks have nearly doubled, sending the price of coal to an all-time high. This has led to a huge increase in fossil-fuel power station costs and even pressure to lose money

(Coal Price curve)

2 China has seen a 20.6 per cent surge in factory use as global orders pour into the country following the outbreak in south-east Asia.China’s foreign trade enterprises are full of orders, some orders are even scheduled for next year, so the factory overtime to start production. On the supply side, coal is up, costs are up, and on the demand side, electricity demand is up. This one comes and goes, causing a strain on the power.

China limits production! The global supply chain is freaking out! Shelves in US and UK supermarkets are empty after another shopping spree

Global orders have flooded into China in the wake of the epidemic in Southeast Asia. Recently, the Chinese government tried to force “High-input, high-energy consumption and high-emission”enterprises to upgrade their industries and step out of their comfort zone to avoid falling into crisis, the state promulgated a double-control environmental protection policy.

Provinces such as Guangdong, Zhejiang and Jiangsu, which have been “Named”by the National Development and Reform Commission, have introduced measures to limit electricity consumption to ensure that the double target can be achieved in a timely manner.

At the same time, some countries in Europe and the US, which rely on Asian manufacturing, are caught up in fears of inflation and supply chain strains, as people hoard necessities.

1 Costco in panic buying

The shelves at Costco, America’s largest chain of member-owned warehouse stores, are empty again, a panic buying spree driven by a supply-chain crisis and soaring logistics costs.

Because it is precisely the time when American businesses are gearing up for the holiday season at the end of the year, as consumers prepare for the holiday season and head to the supermarket to snap up items.

But the soaring cost of logistics and the crisis in the supply chain make the goods in short supply and, unsurprisingly, the shelves are snapped up.

In response to the supply chain crisis, the opening of the market announced that the United States will be toilet paper, cleaning products and bottled water and other household items to re-impose restrictions.

2 Fed Chairman says prices are rising

“Surveys show that American households believe prices will rise in the short term,”fed chairman Powell said recently, highlighting the “Short term”but the fact that households generally believe prices will continue to rise.

Costco’s chief financial officer called logistics costs “A long-term inflation factor”on the earnings call, adding to a combination of rising labor costs, increased demand for products and higher commodity prices, inflationary pressures have intensified.

“We can’t bear all the pressure, and some of it is bound to be passed on to consumers,”he said, predicting a 3.5-4.5 per cent increase in the overall price of products sold by opening customers.

Among them, the price of paper products for daily use rose by 4% to 8% , and the price of pet products rose by 5% to 11% . In addition, the opening of the market may next year to increase the annual membership fee, an increase of about 8% .

And the company now has to solve the problem is “Commodity shortage.”. In an attempt to ease the “Commodity crunch”, traders will charter three ocean-going vessels to and from North America and Asia next year, but that measure may fall far short of addressing the immediate supply-chain crisis.

3 Panic buying in UK supermarkets

At the same time, the UK is facing a “Buying spree”.

With energy prices rising, Brexit, a shortage of labour, a shortage of truck drivers and rising inflation expectations, supply chains are tight, goods are scarce and drinks and meat in British supermarkets are in short supply, there has been a panic buying by British residents, a panic buying in British supermarkets, and shelves have been snapped up.

This, in turn, will drive up inflation in the UK

The 12-month average CPI inflation rose to a nine-year high of 3.2 per cent in August from 2.0 per cent in July, according to the Bank of England.

If inflation stays high in the medium term, even if the Bank of England has cut its growth forecast for the third quarter to 2.1% from 2.9% , the economy will suffer.

4 Inflationary pressures in many parts of the world

Indeed, inflationary pressures are already widespread in the world’s advanced economies.

The Eurozone has also been caught up in the turmoil.

Inflation has also risen sharply in the eurozone as a result of tight energy supplies. The surge in energy prices, such as natural gas, has led to a sharp rise in electricity prices, forcing a number of European companies to cut production and halt production, leading to a lack of optimism in the European supply chain.

The Organisation for Economic Co-operation and development expects inflation in the eurozone to hit an all-time high in the fourth quarter.

In addition to the United States, the United Kingdom, the Eurozone, the current Russia, Brazil, India, Turkey, South Korea, New Zealand, Malaysia, Thailand and other countries are very serious inflationary pressure.

In copper, aluminum and other high prices of bulk materials, the photovoltaic industry where to go

Although the price of coal has skyrocketed, and in order to achieve carbon neutrality, carbon has peaked. In the future, we must vigorously develop photovoltaic power generation

With global inflation, the prices of all raw materials will only go up, which means the PV industry will have to start thinking about costs, because PV is a clean, renewable energy source, but with the current technological capabilities, the efficiency of photovoltaic generation is still not high enough.

1 China’s massive restrictions on electricity use are bound to lead to a decline in production capacity and the closure of small and micro enterprises

Chemicals, iron ore, thermal coal and other commodities generally skyrocketed, raw materials commodities are almost consistent overall price increases. This has not led to an increase in the prices of industrial goods, the surge in the prices of raw materials and the difficulty of raising prices in the lower reaches of industrial goods, which means that the entire manufacturing sector is “Earning capacity but not making money”. Busy with production, but the profits are shrinking. It can be seen that the foreign trade export manufacturing enterprises are facing a bizarre scene: on the one hand is orders Crazy Drop, on the other hand is to take orders but do not make money.

Although raw materials have soared, the price of downstream manufactured goods will ultimately depend on supply and demand, not just on costs. In fact, because of the epidemic raging in Europe and the United States, the overall consumer demand is in a substantial decline. The reason why China’s manufacturing capacity and export orders are currently off the charts is because overseas epidemics have disrupted overseas manufacturing industries, this has forced some overseas manufacturers to place orders in the world’s only manufacturing power to contain the outbreak.

The current surge in exports is more like a bounce-back for a weakened world economy. There is an abnormal situation in which the prices of raw materials in the upper reaches soar, but the prices in the lower reaches remain unchanged. In fact, the current surge in raw material prices is not in itself a normal marketization.

So the future of large-scale PV product price increases must be inevitable

2 Aluminum alloy cable is an excellent solution

Copper-core cable occupies an absolute advantage in the cable market. The advantage of copper-core cable is not much, but the price of copper can not be ignored, which leads to the increase of production cost. And it’s not easy to build. Therefore, in recent years we turn to the aluminum alloy material. The aluminum alloy cable rises suddenly, receives the market the favor, the traditional copper core cable user may have the question, aluminum alloy cable can replace the aluminum core cable? Compared with the traditional copper-core cable, what are the outstanding advantages of aluminum alloy cable?

1. Tensile strength and elongation

Compared with pure aluminum conductor, aluminum alloy conductor, because of the addition of special components and the use of a special processing technology, greatly improved the tensile strength, elongation to 30% , more safe and reliable use.

2. Creep resistance

Compared with pure aluminum, the creep resistance of aluminum conductor is improved by 300% , and the relaxation problem caused by cold flow or creep is avoided.

3. Coefficient of thermal expansion

The Coefficient of thermal expansion is used to calculate the size of the material as the temperature changes. Aluminum alloys have the same Coefficient of thermal expansion as copper, and aluminum connectors have been reliably used for copper and aluminum conductors for years, and most electrical connectors in use today are made of aluminum, which is especially suitable for aluminum alloys. So the aluminum conductor and the connector expand and contract exactly the same.

4. Corrosion resistance

The inherent corrosion resistance of aluminium is due to the formation of a thin, strong oxide layer when the aluminium surface comes into contact with air, which is particularly resistant to various forms of corrosion. The rare earth elements added in the alloy can further improve the corrosion resistance of aluminum alloy, especially the electrochemical corrosion. Aluminum’s ability to withstand harsh environments has led to its widespread use in conductors for cables in pallets, as well as in many industrial components and containers. Corrosion is usually associated with the bonding of different metals in a humid environment and can be prevented by the use of appropriate protective measures, such as lubricants, antioxidants and protective coatings. Alkaline soils and some types of acid soils are highly corrosive to aluminum, so directly buried aluminum conductors should be insulated or moulded to prevent corrosion. In sulphur-containing environments, such as railway tunnels and other similar places, aluminium alloys are much more resistant to corrosion than copper.

5. Connectivity

Electrical connections made of aluminum alloys are as safe and stable as those made of copper conductors. The composition of the aluminum alloy greatly improves its connection performance. When the conductor is annealed, the added iron produces high strength creep resistance, which ensures the stability of the connection even under long-term overload and overheating.

6. Strong self-bearing capacity

Aluminum alloy improved the tensile strength of pure aluminum, aluminum alloy cable can support 4000 meters of weight, copper cable can only support 2750 meters. This advantage is particularly evident in the wiring of large-span buildings such as stadium.

7. Flexibility

Aluminum alloy has very good bending properties, its unique alloy formula, processing technology, so that the flexibility greatly improved. Aluminum alloys are 30% more flexible than copper and 40% less resilient than copper. Generally, the bending radius of copper cable is 10 ~ 20 times outer diameter, but the bending radius of aluminum cable is only 7 times outer diameter, so it is easier to connect terminals.

8. Compression characteristics

In terms of volume conductivity alone, aluminum alloy is not as good as copper, but the conductors we have developed have not only improved in material properties, but also made great breakthroughs in technology, it is the first time in China that the compaction coefficient can reach 0.93 and the compaction coefficient of the profile can reach 0.95. Through the maximum compression limit, it can make up the shortage of aluminum alloy in the volume conductivity, make the stranded conductor core as solid conductor, obviously reduce the core diameter, improve the conductivity, the outer diameter of the conductor is only 10% larger than that of the copper cable at the same current carrying capacity.

2021-09-29

2021-09-29