Since the goal of “carbon peaking in 2030 and carbon neutrality in 2060″ was put forward, the energy storage industry has been vigorously developed in China, which has brought another development opportunity to energy storage connector companies, but there are still many challenges.

In modern society, energy consumption is increasing day by day, and the extensive use of fossil fuels has irreversibly adverse effects on the environment and the global climate. The data shows that, if calculated based on the existing mining technology and the current rate of consumption of fossil fuels, the useful life of fossil fuels will not exceed 120 years at most, and the goal of sustainable development of mankind will face serious threats. Therefore, the research and development of new energy and renewable energy, and the search for advanced methods to improve energy utilization have become the primary issues of common global concern, and the energy storage industry has gradually entered the public’s field of vision.

Since the goal of “carbon peaking by 2030 and carbon neutral by 2060″ was proposed, China has issued a number of policies one after another. According to China Energy Storage News Center’s incomplete statistics, only in August 2021, China’s administrative and regulatory agencies issue a total of 22 energy storage-related policies, which shows that China’s determination to vigorously develop the energy storage industry, coupled with the business model of energy storage continues to establish, the installed capacity of energy storage is exploding, the energy storage market is as strong as ever. Energy storage connector as an essential component of the energy storage industry, its market capacity, product demand also grows with the development of the energy storage industry, energy storage connector how to develop healthily under this trend? Chinese companies and how to take root in the energy storage industry chain?

The energy storage industry is developing rapidly, and the market is gradually expanding

●Electricity market: new energy power generation is unstoppable, and the energy storage industry is developing

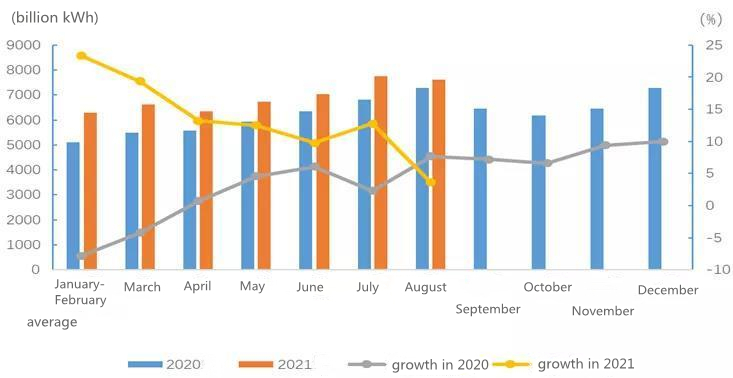

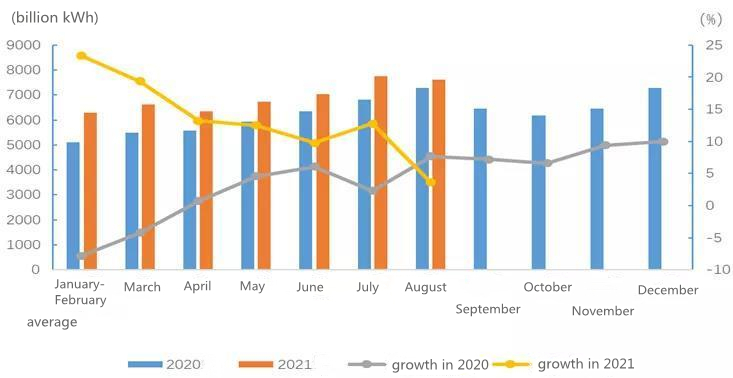

With economic development and social progress, China’s electricity demand continues to increase. On September 14, 2021, the National Energy Administration released data on the electricity consumption of the whole society in August. From January to August, the total electricity consumption of the whole society was 5,470.4 billion kWh, a year-on-year increase of 13.8%. In terms of different industries, the electricity consumption of the primary industry was 66 billion kWh, a year-on-year increase of 19.3%; the electricity consumption of the secondary industry was 3,652.9 billion kWh, a year-on-year increase of 13.1%; the electricity consumption of the tertiary industry was 953.3 billion kWh, a year-on-year increase of 21.9%; the domestic electricity consumption of urban and rural residents was 798.2 billion kWh, a year-on-year increase of 7.5%.

Under the goal of “carbon peaking and carbon neutrality”, new energy power generation has gradually become an important force in power supply, and the wind power photovoltaic industry has developed rapidly. It is reported that in the first quarter of 2021, China’s photovoltaic module output exceeded 30GW, a year-on-year increase of 40%; the domestic installed capacity was 5.3GW, a year-on-year increase of 34%, and will continue to maintain a rapid growth momentum, that is, in this momentum, the energy storage market welcomes came explosive growth.

New energy generation has eased the pressure of fossil energy consumption in China to a certain extent, but there are problems of randomness and volatility. Energy storage technology can help smooth the output of new energy generation and effectively regulate the changes of voltage, frequency and phase of the power grid caused by new energy generation, so that large-scale wind power and photovoltaic power generation can be integrated into the conventional power grid easily and reliably.

According to statistics, by the end of 2020, the cumulative installed scale of energy storage in China is 3.28GW, which is still 10 times short of the 30GW installed scale of energy storage in 2025 proposed by the National Energy Administration and National Development and Reform Commission. In the first half of 2021, the installed scale of new energy storage in China has exceeded 10GW, a six-fold increase year-on-year, and less than three times away from 30GW.

●New energy vehicles: The market penetration rate continues to rise, and the demand for energy storage is gradually increasing

As the core technology of power batteries, the good situation of new energy vehicles has greatly promoted the development of the energy storage industry. The latest data released by the China Automobile Association shows that in August, domestic automobile production and sales reached 1.725 million and 1.799 million respectively, down 18.7% and 17.8% year-on-year, respectively. As of the end of August, my country’s automobile production and sales have declined year-on-year for four consecutive months. However, the domestic new energy vehicle market is completely different from the continuous downturn of the overall auto market. Data show that in August, domestic production and sales of new energy vehicles completed 309,000 units and 321,000 units respectively, an increase of 1.8 times year-on-year, production and sales continue to set new records and exceed 300,000 units for the first time.

The rapid growth in sales of new energy vehicles has led to a gradual increase in the penetration rate of the domestic new energy vehicle market. According to data from the China Automobile Association, from January to August, the cumulative sales penetration rate of new energy vehicles in my country increased to nearly 11%. Among them, in August, the penetration rate of domestic new energy vehicles reached 17.8%, and the penetration rate of new energy passenger vehicles was close to 20%. As far as the current development situation is concerned, my country is expected to achieve the medium and long-term development planning target of 20% of the new energy vehicle market penetration rate as soon as possible, and high-efficiency energy storage batteries will also gradually replace the internal combustion engine.

Energy Storage Connector Opportunities and Challenges Coexist

It has been more than ten years since the development of energy storage. Although energy storage is not an emerging technology, the industrial development is still in its infancy. In the early days, the energy storage industry was not supported by the state’s explicit policy and was completely controlled by the market. Compared with the photovoltaic industry, the energy storage industry developed at a slower pace, the demand for energy storage connectors was less, the business model was uncertain, and the cost Therefore, there are few Chinese connector companies involved in the energy storage field, and foreign energy storage connector companies occupy the dominant position.

Driven by national policies, the energy storage market has gradually expanded, and new energy industries such as photovoltaics, wind power, and automobiles have also been better developed. In 2021, China announced a series of good news to stimulate the development of energy storage. New energy storage application scenarios continue to emerge, and the energy storage industry presents an unstoppable trend. As a key component in the energy storage system, the market capacity of energy storage connectors has increased significantly, which is a major development opportunity for domestic energy storage connector companies.

The market capacity of energy storage connectors will be on the rise for at least the next few decades. The cost of energy storage connectors is low, and the technical threshold is low. Now, thanks to the support of national policies, more and more Chinese connector companies have joined the energy storage industry chain.

However, pressure on energy storage connector cost and quality comes with it.

The material, quality and surface treatment of energy storage connectors all have fixed requirements. With the development of energy storage, the quality standards of connectors will also change. It is understood that the raw materials for making energy storage connectors are mainly plastics and copper alloys. In terms of plastics, nylon and PBT are mostly, and copper alloys generally include copper, vanadium copper and beryllium copper. Among them, nylon and beryllium copper are mainly imported, while PBT, red copper and vanadium copper are mainly domestically produced.

China’s domestic copper technology has been very perfect, which can fully meet the requirements of energy storage connectors for copper, including the copper used in Tesla now, all of which are made in China, but beryllium copper will still be imported.

Dongguan Slocable Solar Technology Co., Ltd. believes that there are still some differences between domestic energy storage connectors and foreign connectors in terms of reliability and consistency, especially foreign brands such as Amphenol and Molex. The production of the device, the selection of materials and the details of the production process have their own unique patents and technologies. Domestic connector companies should increase the research and development of energy storage connectors, and strengthen the details of the connector in the process of manufacturing, so as to narrow the gap with foreign brands.

How Can Energy Storage Connectors Continue to Develop Healthily?

1. Clarify the cost reduction plan

As mentioned above, the market volume of energy storage connectors is gradually increasing, and the cost problem has become a major problem for connector companies. In recent years, the cost of electrochemical energy storage batteries has gradually decreased, so the cost control of installed capacity has become particularly important. As a key component of installed connection, the cost of energy storage connectors has become the main consideration when selecting products. How to reduce product costs and meet future energy storage development is a big challenge for energy storage connector companies.

Energy storage connectors have two relatively common connection methods – fixed screw connection and quick-plug connection. As an economical connector design, the fixed bolt connection cost is low, which can meet the cost-effective requirements of some customers, but the safety and convenience are relatively poor. In contrast, the quick-plug connection has obvious advantages in safety and reliability, but the cost is relatively high.

The structure of the energy storage connector is simple and the threshold is not high. Many connector companies have this technology, so the cost advantage is particularly important when the quality is consistent. For a product, under the premise of ensuring performance and quality, the simpler the design, the lower the cost, and the higher the level of performance. In addition, improving production efficiency is also a measure to achieve cost reduction.

Slocable said that in the face of cost pressure, under the premise of ensuring the quality of the connector, our company first started from the source of product design, improved the structure, and designed the plug of the energy storage connector into an assembled structure (the company has applied for an invention patent), reducing It meets the precision requirements for tooling, molds and equipment in the manufacturing process.

Secondly, Slocable also minimizes the number of key dimensions of related components, reduces the difficulty of finishing metal parts, and realizes self-made key components of the connector. For example, the core terminal of the connector adopts its own design and production method, which not only reduces the cost of raw materials but also ensures product quality from the source.

2. Guarantee product quality

High-quality energy storage connectors should mainly have the characteristics of safety, reliability and consistency.

Safety is the primary criterion for the quality of key components, regardless of the development of the industry, are to be based on safety, otherwise the industry will encounter risks again. Secondly, the reliability of the energy storage connector is also particularly important, the life of the energy storage system is about 15 years, the energy storage connector is a key component inside the entire system, its life is related to the entire energy storage system can guarantee 15 years is safe and effective operation.

There are a large number of energy storage batteries in the energy storage device, and the energy storage batteries are connected in series and parallel through the energy storage connectors to form high voltage and high current output or storage. As a key component of transmission, energy storage connectors are used in thousands, and how to ensure the consistency of thousands of energy storage connectors has also become a major consideration for connector companies.

Then, how to ensure the quality of energy storage connectors?

Starting from the selection of materials, functions and electrical performance of energy storage connectors, Slocable integrates the functions of positive and negative anti-mistake insertion, electric shock prevention, waterproof and 360 degree rotation, etc. Through a lot of research and practical cases, Slocable has independently developed the core terminals of the connectors and made efforts to reduce the degree of terminal attenuation, which ensures the safety, reliability and consistency of the products while reducing the cost.

When choosing plastic materials, our company will have specific considerations, such as color fading, shrinkage, pressure resistance, strength, etc., so the company will conduct a lot of tests to select suitable materials before choosing a supplier.

Overall, in order to reduce costs while ensuring quality, you need to start from the design of the connector as well as the production chain, continuous innovation and upgrading in technology, have their own core technology, simplify the structure, reduce production links, control costs from the source to ensure quality.

If you are interested in Slocable’s high current energy storage connectors, you can read this article: Slocable Has Successfully Developed the Energy Storage Connectors.

Summary

Since the “double carbon” goal, the whole country is working hard for it. With the support of national policies, the energy storage market is breaking new ground, the demand for energy storage connectors is also rising, due to the low technical threshold, the energy storage market to many connector companies have brought development opportunities, more and more Chinese connector companies to join the energy storage industry chain. However, there are still challenges in the development process, the increasing demand for materials, how to choose, how to control costs, how to ensure quality is the energy storage connector companies need to consider the issue of meeting the technical requirements of the premise that the cost advantage will become a measure of the connector companies a major criterion.

2023-08-14

2023-08-14